|

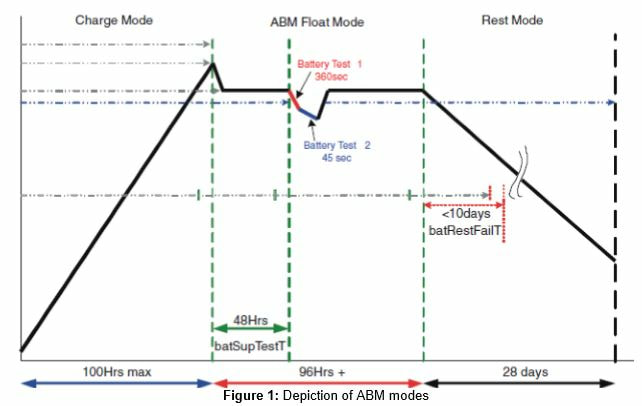

Introduction The battery system in a UPS represents the heart of the power protection benefit. This key element performs two functions: (1) it delivers energy during a power outage, and (2) it stores energy efficiently for extended periods of time. That stored energy is instantaneously available when needed to support the critical load on the UPS. In order to perform the above functions reliably, the charge level of the battery must be maintained. At the same time, battery charging should be controlled to maximize system efficiency and, more importantly, to maximize the float service life of the battery system. Two types of battery charging schemes have traditionally been used for UPS battery systems. The older and more commonly known is the “float” charge, which involves applying a constant voltage charge to the battery continuously for purposes of maintaining full charge during day-to-day operation of the UPS. This works quite well in many conventional battery applications. However, battery life may not be optimal, due to overcharging, for batteries that are used very occasionally as in standby applications such as a UPS. In a UPS, the battery system may sit in float mode for many months, without ever experiencing a discharge. Float charging for long periods of time means that “trickle charge” energy is constantly forced into a battery which is effectively already full. This results in very gradual degradation of the lead plates (positive grid corrosion), and it can impact float service life. Standby applications are better suited for “opportunistic” charging schemes. The system Eaton® utilizes is called ABM technology, which is essentially a set of charger controls and automated battery tests. It is implemented in Eaton single-phase UPSs from 500 VA to 18 kVA and three-phase models from 10 kVA to 3.3 MVA. Opportunistic charging schemes like ABM allow for periods of time where the battery is being fully charged, and periods of time when the charger is disabled. This reduces the time that the battery is subject to grid corrosion when compared to a traditional float charger — a reduction in grid corrosion that yields a measurable increase in battery life for UPS applications. ABM Operational Summary As shown graphically in figure 1, ABM consists of three operating modes:

Charge Mode The UPS enters the charge mode under any of the following conditions:

In charge mode, constant voltage charging of the batteries is used to recharge a discharged battery after a power outage, or whenever the ABM process is restarted. Charge voltage target is set to the manufacturers’ float level, and charge current is greater than 0.1 C A. Constant voltage charging lasts only as long as it takes to bring the battery system up to a predetermined float level (there is a 100-hour maximum time limit). Once this level is reached, the UPS battery charger remains in constant voltage mode, maintaining a float level. The current is at trickle charge levels during this time, and a 24-hour clock is started. At the end of 24 hours of float charging, the UPS automatically performs a battery test (see figure 1) at two different load levels to verify that the battery is performing, and to collect data for comparison to previous and subsequent automatic battery tests. If the test fails, an alarm is activated on the UPS and also through the remote monitoring system that may be connected to the UPS. At the end of the test, the charger resumes constant voltage mode and remains in that state for an additional 24 hours. Rest Mode Rest mode begins at the end of charge mode; that is, after 48 hours of float charging, and after a successful battery test. In rest mode, the battery charger is completely turned off. The battery system receives no charge current during this mode, which lasts about 28 days. Then, the charge mode is repeated as described above. Since the battery clearly spends most of its time in rest mode, as a result, the following benefits are realized:

During rest mode, the open circuit battery voltage is monitored constantly, and battery charging is initiated if any of the following occur:

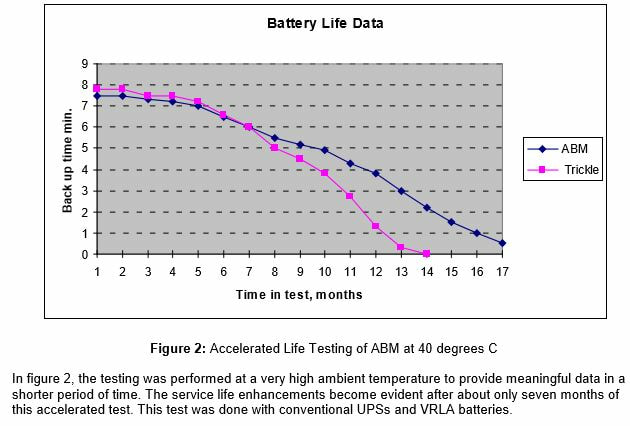

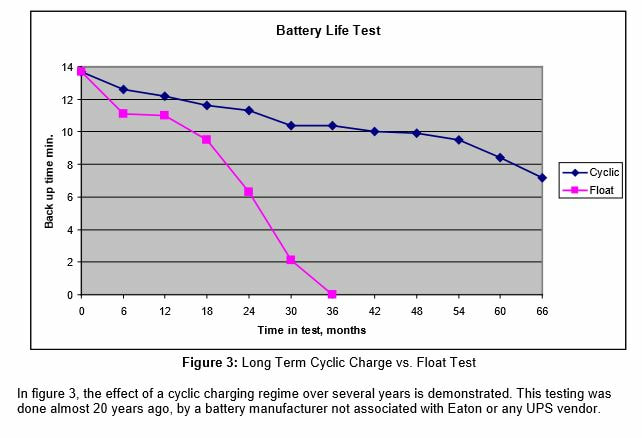

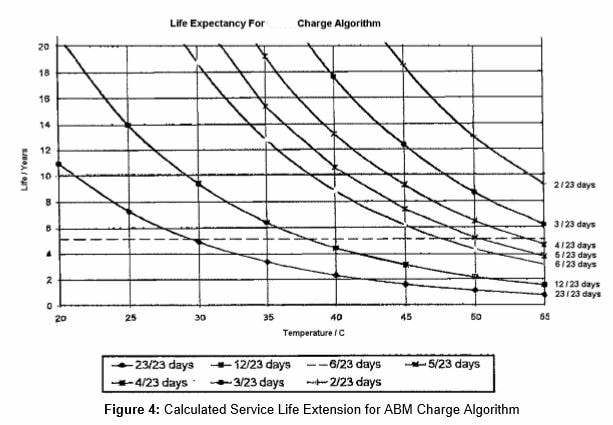

Test Mode There are two other battery tests that are performed as a part of the ABM cycle. The first is meant to detect battery conditions which could lead to thermal runaway. The bulk charging period is timed and if the float voltage is not reached in a predetermined time, an alarm is triggered and the charger is shut down. The second test is performed after the charge cycle is completed (i.e., at the beginning of rest mode). The battery is discharged at about 15% load for up to 6 minutes, then at 50% load for 45 seconds.. Upon reaching this point, the battery voltage is measured. If the voltage is below a specified threshold, dependent on the load, then an alarm is signaled indicating the battery is nearing the end of its service life and should be replaced. Other Modes ABM may be disabled by the user or an Eaton field technician at any time. In this case, the UPS battery charger operates as a conventional float charger only. This is recommended when a wet cell or flooded electrolyte battery is used with the UPS. ABM is intended for use with VRLA batteries. As a result, wet batteries do not benefit from ABM controls. Many observers express concern regarding the ability for the battery to maintain capacity if called upon to support the UPS near the end of its rest mode. In other words, how much battery capacity is available on day 27 of a 28-day rest mode? Using a 15-minute battery as an example, under this condition, the battery would provide all but about 30 seconds of its 15-minute backup time. This is proportionally true for other battery sizes, as well. The intent in selecting the 28 day rest period is to limit the loss of capacity to approximately 5%. ABM Performance The ABM process above describes the benefits of using a “opportunistic” charging scheme. Those benefits, specifically extended service life, are in fact substantiated by data and empirical testing performed by Eaton as well as other independent sources. Some of this testing is recent and some of it was performed as many as 25 years ago. ABM is not a new battery management feature. In fact, Eaton has been using ABM in its UPS products for 27 years, and it has proven itself beneficial in the field for more than two decades. Note that in figure 4, the curve identified as “23/23 days” represents a float charger, and ABM (as implemented today) is best represented by the curve labeled “12/23 days.” At an ideal 25°C (77°F), there is a theoretical increase of six years in battery service life reflected in this analysis.

The above information shows a clear benefit of cyclic charging in UPS applications, both in simulated and in actual performance tests. These results would not be expected with non-VRLA batteries or in applications such as motive power chargers where the battery is discharged/recharged daily and therefore not deployed in a standby application. Summary ABM is unique in the UPS industry, but similar opportunistic designs are utilized by battery manufacturers and battery charger designers worldwide. The criticality and cost of the battery subsystem of any UPS dictates that special consideration be given to battery longevity. Additionally, with environmental concerns relating to battery removal and disposal becoming more prevalent, it is desirable to reduce the frequency of battery replacements during the life of the UPS electronics. ABM offers a significant benefit over conventional “battery monitors” which don’t provide charging control, and “multi-stage chargers” which protect the battery, but do not provide useful extension of battery service life. Over the past 27 years, ABM has proven itself in both large and small UPS products, from the desktop to the data center, and from the medical lab to the factory floor. Anywhere a UPS is installed, a battery system is depended upon to provide backup power protection for critical business processes and even for personnel safety. The battery is all too often ignored as a maintenance-free product, not requiring attention or inspection. This neglect, though common, can be costly and possibly disastrous. The ABM system, by its nature, helps to provide early detection of problem batteries and thus protect the battery from unnecessary failures like electrolyte dry out and thermal runaway, while functioning to extend the useful life of this key component of power quality.

3 Comments

|

AuthorBrisk Worldwide is Your #1 Technology, Power & Lighting Resource! Archives

November 2023

Categories

All

|

|

At Brisk Worldwide , our customer is our main priority.

Serving commercial, data centers, contractors, property managers, and businesses, we offer a huge selection of uninterruptible power supply systems, backup power systems, and power management systems for large Data Centers, electrical engineerIng infrastructure, and other mission critical IT applications. So if you need help or you just want a hand placing your order, we can assist! |

Connect With Us |

RSS Feed

RSS Feed